Tadafumi Adschiri Laboratory, Tohoku University

Summer 2018

Skills

Lab: Ultraviolet–Visible Spectroscopy, X-Ray Diffraction, High-Performance Liquid Chromatography, Transmission Electron Microscopy

Computer: MATLAB, OriginPro, Excel, PowerPoint

Language: Japanese

Team

Paired with PhD Candidate

Awards

Honors College Alternative International Experience Scholarship

Paid Research Internship at The Advanced Institute of Material Research

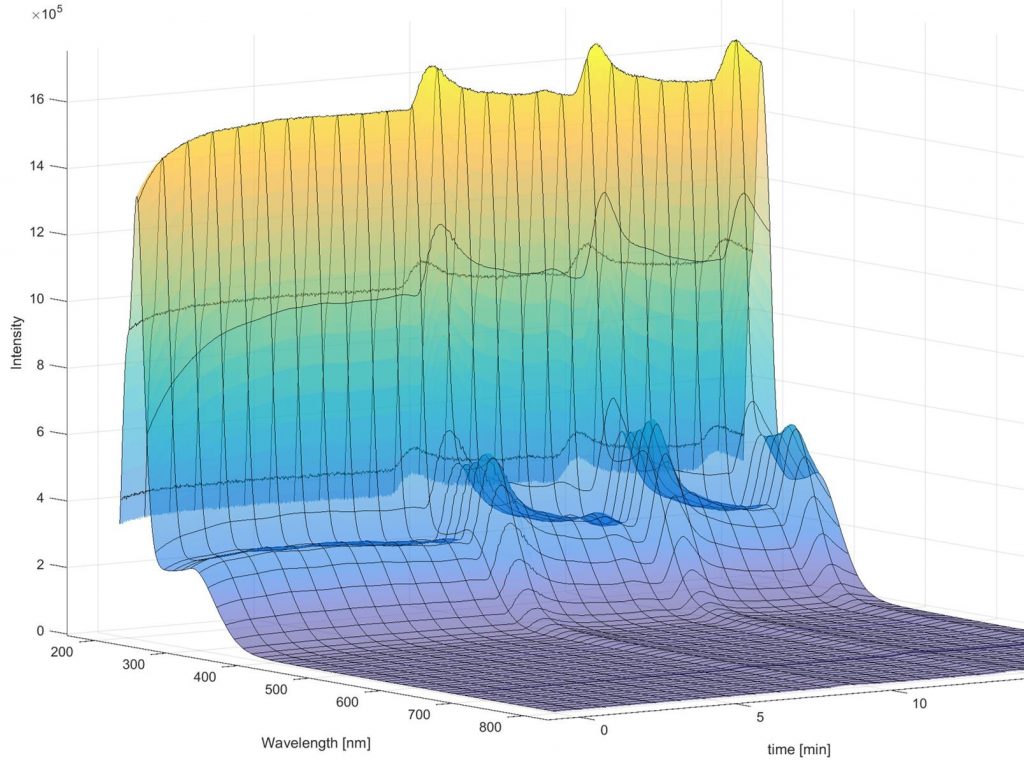

UV-Vis of CeO2 production demonstrating batch production (agglomeration).

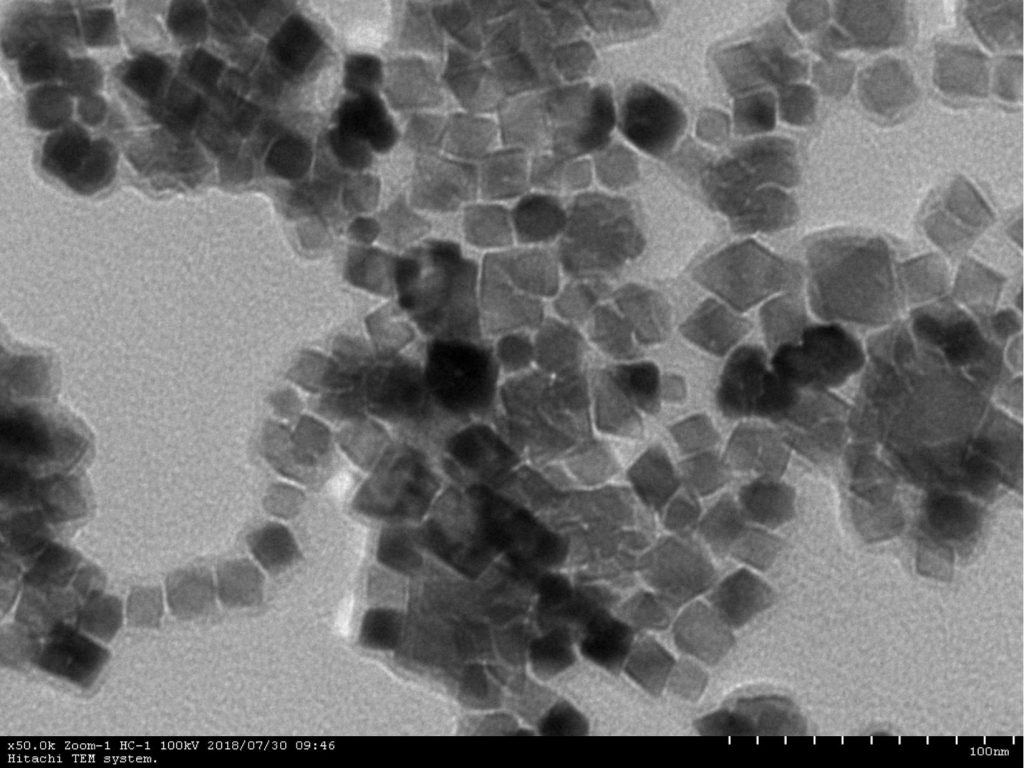

Rapidly nucleating metal oxide nanoparticles through violent and sudden mixing with supercritical water in a continuous flow reactor circumvents current limiting factors in nanoparticle synthesis, such as precursor cost and scalability. Therefore, I researched the synthesis of CeO2 nanoparticles, a material used in solid oxide fuel cells and as a catalyst or photocatalyst, through a continuous supercritical hydrothermal reactor.

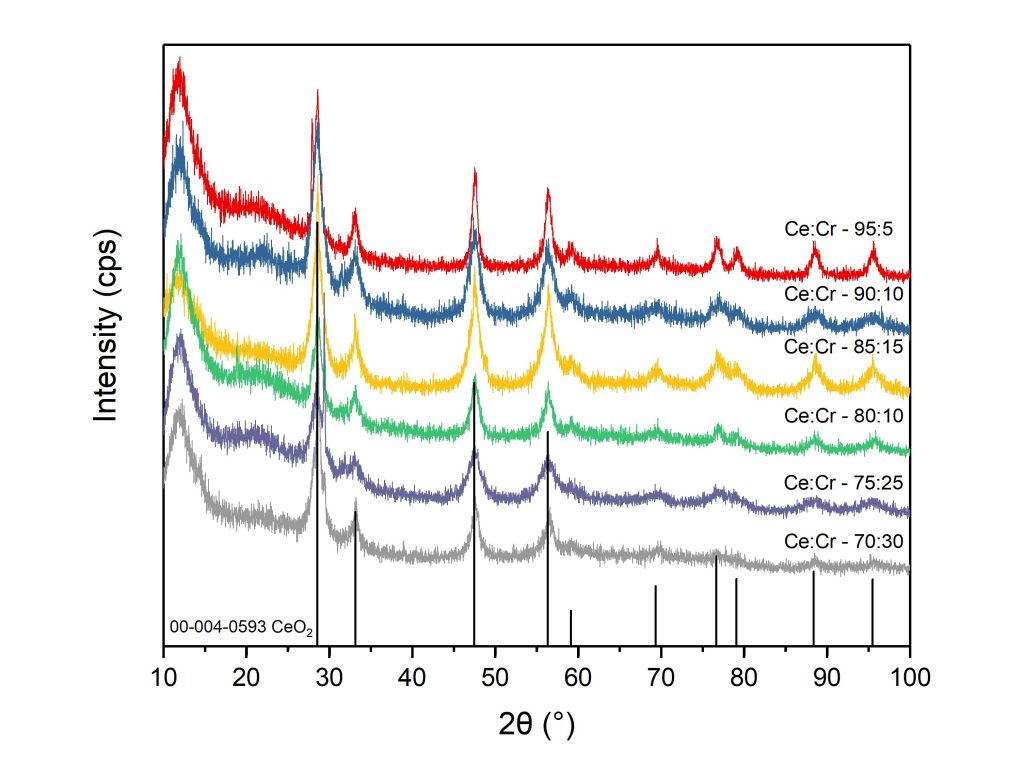

My work included designing a reactor system that promoted deagglomeration and in-line UV-Vis characterization, and testing the addition of dopants to the CeO2 particles. The synthesis process involved maintaining consistent temperature and pressure values above supercritical values, but below maximum pressure operating ranges. I also automated the flow schedule of various precursors to accurate proportions.

XRD of varying Cr dopant concentration in CeO2.

TEM image of CeO2 nanoparticles.

In-line UV-Vis characterization was used for identification and catalytic activity. XRD, TEM, and Zeta Potential characterization were conducted on final products for doped structure analysis, size analysis, and deagglomeration purposes.